Produck offers the possibility of outsourcing the manufacture of its products through the services of 3D printing, CNC machining of plastic and metal, vacuum casting (silicone molds) of resins, plastic injection and metal casting.

Manufacturing Services

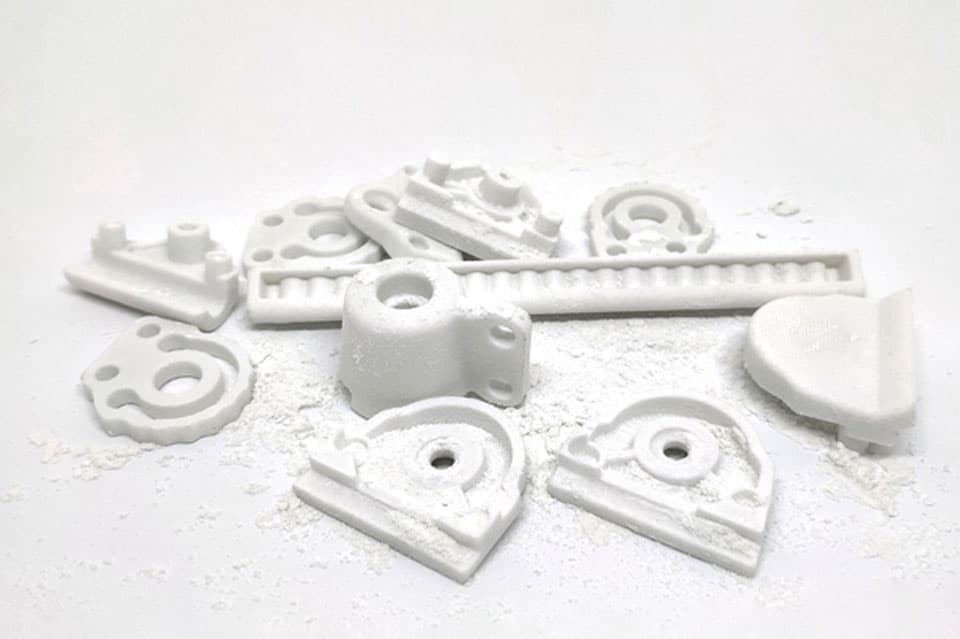

3D PRINTING

3D printing in its variants of stereolithography (SLA) or Selective Laser Sintering (SLS) is an ideal technology for prototypes and short series commonly used in different sectors.

Common applications

- Formal and / or functional validation

- Production of prototypes and short series

- Manufacture of unique complex parts

CNC PLASTIC MACHINING

The machining of plastics is an excellent technology for the manufacture of rapid prototypes, as well as for the production of short series of plastic parts.

Common applications

- Prototype and short series

- Pre-injection validation

- Visual models

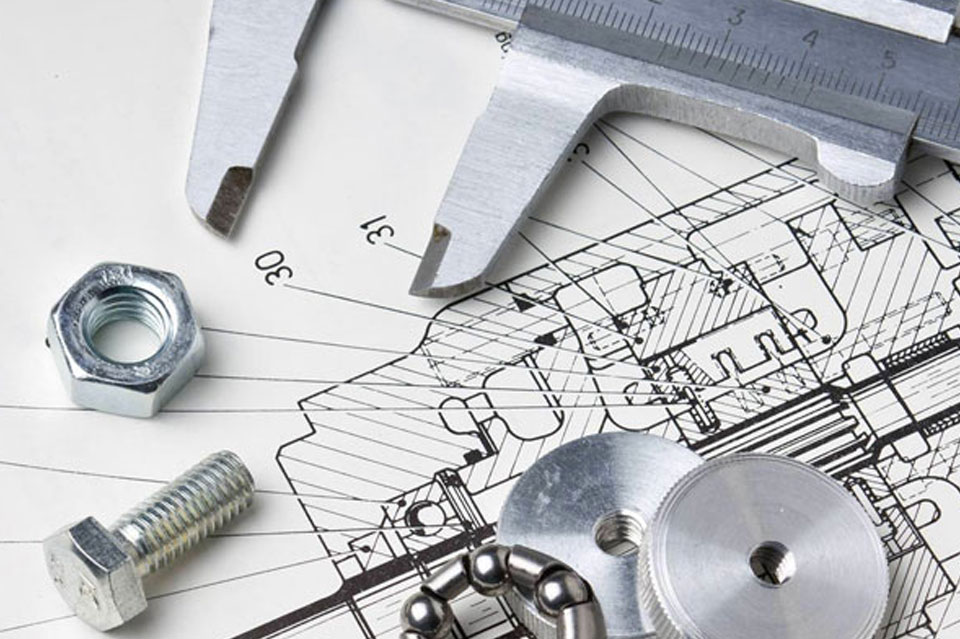

CNC METAL MACHINING

Metal machining is the ideal technology for prototypes or short series. At Produck we machine metal parts with accuracies of up to 0.025mm

Common applications

- Prototypes and short series

- Pre-production validation

- Visual models

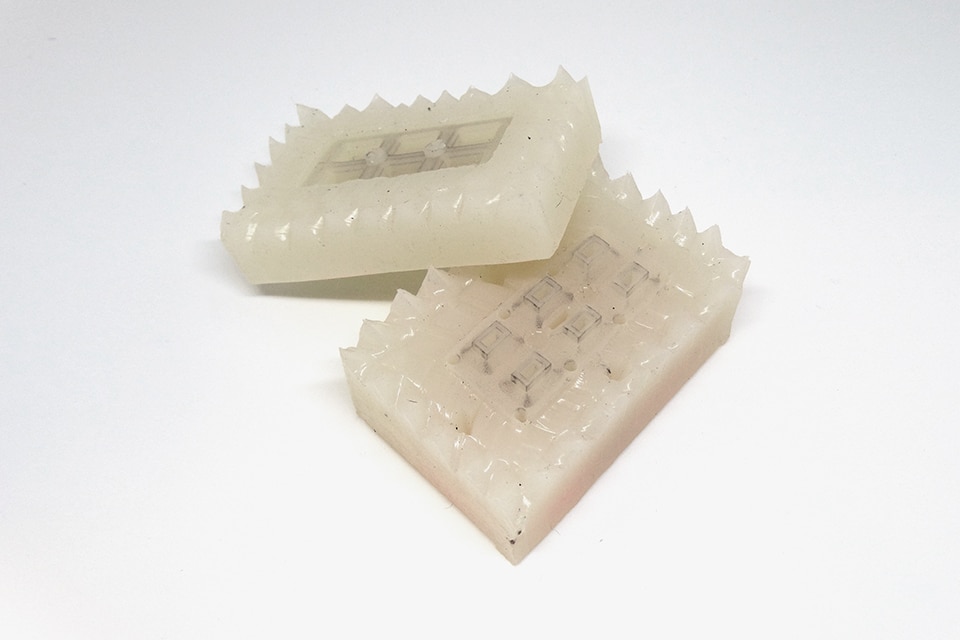

VACUUM CASTING

Vacuum Casting, or Silicone Molds, allows us to obtain parts with a finish very similar to plastic injection, avoiding such a significant investment.

Common applications

- Short series

- Visual pieces

- Pre-series of market testing

PLASTIC INJECTION

Injection of plastics or injection molding is the ideal manufacturing technology for high production volumes, achieving very competitive unit prices and quality.

Common applications

- Mass production

- High quality surface products

- Plastic parts already validated

METAL CASTING

Metal casting is based on the manufacture of parts from the introduction of a molten material in a mold. Once solidified, it acquires the desired shape.

Common applications

- Serial production

- Automotive, railway, etc.

- Structural and aesthetic pieces

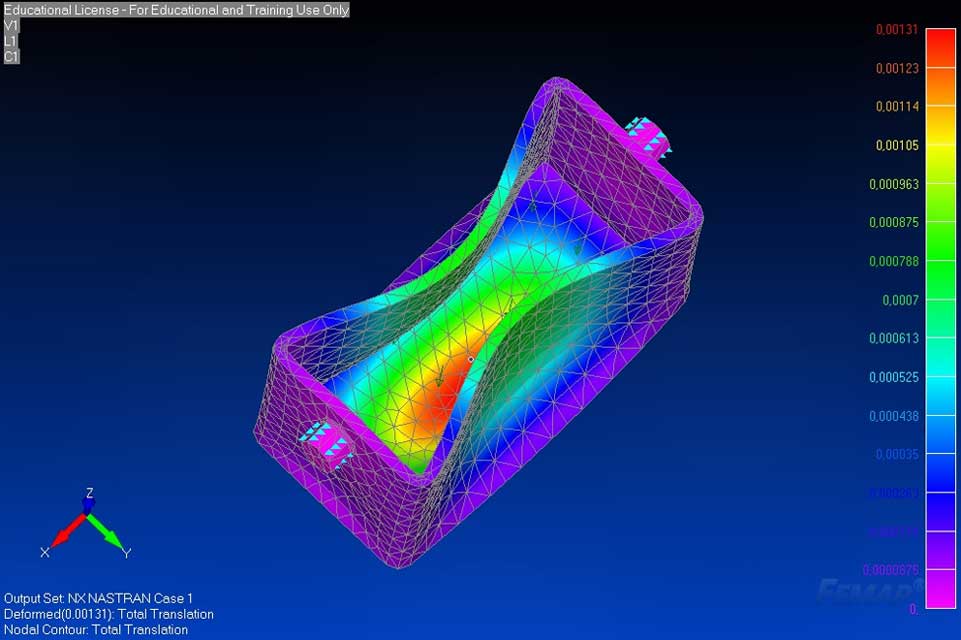

ENGINEERING

We take care of adapting the design of the parts to the different manufacturing technologies. Centralizing engineering and manufacturing at Produck ensures a perfect interface fit.

Examples

- DFM (design for manufacturing)

- Development of parts to adapt them to injection

- Optimization

- Weight optimization study meeting mechanical requirements

LOGISTICS

Product offers you turnkey projects. We take care of all phases of the project, including transportation to the door of your office or warehouse.

Transport options

- By air: express delivery service (3 working days)

- By sea: for loads of bigger weight or volume

OBTENGA BENEFICIOS CON PRODUCK

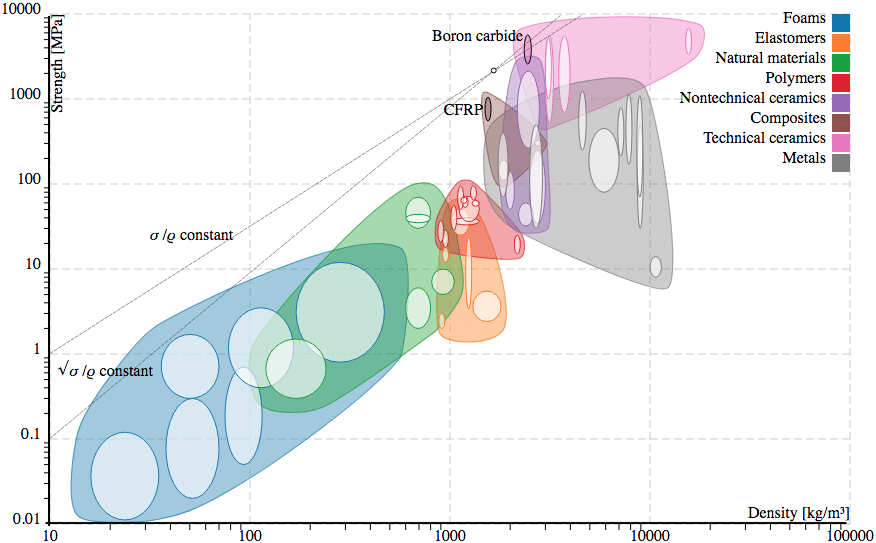

ESCOGER EL MATERIAL ADECUADO

Conozca la simplicidad de los mapas Ashby para elegir rápidamente el material más adecuado.

ESTUDIO DE VIABILIDAD DE TUS PIEZAS

Consulte a un experto sobre la viabilidad de una pieza y salga de dudas en menos de 24 horas.

NDA: ACUERDO DE CONFIDENCIALIDAD

Nos comprometemos por escrito a respetar la propiedad intelectual de las piezas que nos envíes.