Produck can help you on all phases of product development, from designand engineering to prototyping and mass manufacturing.

Design and Development

Market and user research

Experience definition

MVP (Minimum Viable Product)

Industrial Design

Product Engineering

Validations

Patents study

MKT Visualization

Mockups and Prototypes

Functional Prototype

Visual/aesthetic mockup

Rapid prototypes

Realistic finishes

Short Series

Pre-series

Short series

Market test

Toolings & Manufacturing

DFM (Design For Manufacturing)

Molds and Tooling

Mass Production

Quality Control

Packaging

OEM and ODM

Manufacturing technologies

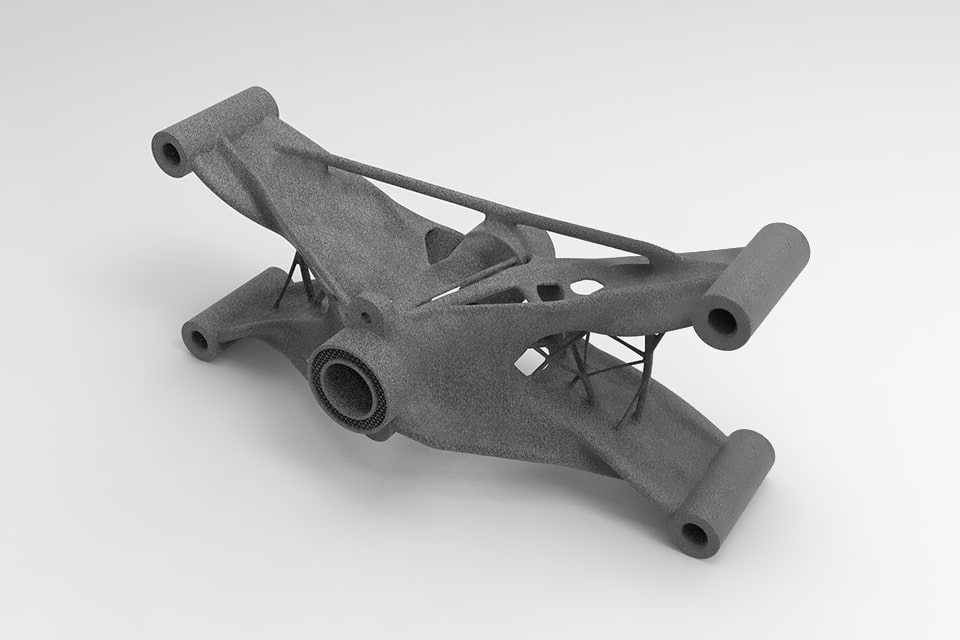

Industrial 3D printing is a manufacturing technology that is based on material addition, unlike traditional methods where a three-dimensional object is created by layering successive layers of material. Subtractive processes often result in significant material waste. With 3D printing, however, we only use the exact and necessary amount of material.

3D printing is capable of creating extremely complex and even impossible-to-make shapes with traditional techniques. This allows us to create designs with never-before-imagined geometries.

- MOQ: 1 piece

- Applications: prototypes and short series

CNC machining is an excellent technology for rapid prototyping and the production of rigid materials, including most metals and plastics.

Moreover, due to its configuration, CNC machining operations allow us to manufacture at an accelerated pace, resulting in cost-effective and highly precise mass production.

- MOQ: 1 piece

- Applications: prototypes, short series and mass production

![]()

Silicone Mold technology is very interesting when it comes to producing short series of plastic parts, typically ranging from 10 to 100 units. Silicone molds are often created from a model obtained through Stereolithography.

Vacuum casting technology is generally used to obtain small or medium-sized parts with intricate details. The wide range of available polyurethane resins allows for a close approximation to the final thermoplastic, resulting in small series of parts that are representative of the final product.

- MOQ: 5-10 pieces

- Applications: Short series

The Injection Mold is the most effective and common system for mass production of parts. It offers excellent quality and finishing, making it essential to have a mold with the best qualities, high precision craftsmanship, and maximum possible durability.

We understand that, in addition to the part design, the mold design is a critical factor for success in industrial injection production. At Produck, we take care of designing, developing, and manufacturing molds with the highest guarantees.

- MOQ: 100 pieces

- Applications: Mass production

Color, material & finishing

Choose the options that best fit the product requirements

QUOTE ONLINE

By using our order assessment system, you can start production within 24 hours with the utmost guarantee of quality and the shortest delivery times in the market.

PROJECTS

WHY US

PRODUCT ENGINEERING

We help you optimize manufacturing processes and provide you with our expertise to achieve more efficient production

QUALITY ASSURANCE

To ensure the quality of the delivered product, we use the Double-Check Method, reviewing your order before it leaves the factory and upon arrival at our offices in Barcelona

TECHNICAL CONSULTING

We provide thorough and personalized monitoring of each project. Our extensive experience in the industrial sector and product development brings a significant advantage to our clients

FAST DELIVERY

Prototype budget in less than 24 hours, prototypes available from 7 days, short series from 2 weeks, and injection molds in less than 1 month

Sourcing & Supply Chain Management in Asia

We help you in your expansion towards the East.